Sistem pemeliharaan broiler di Indonesia tumbuh pesat, yang semula dari peternakan rakyat dengan peralatan manual, sekarang sudah banyak peternakan broiler closed house flooring system dengan peralatan kandang yang otomatis. Mulai dari minum otomatis dengan nipple, pakan otomatis dengan pan feeder, dan pengaturan suhu kandang dengan kipas yang diatur dengan controller. Jumlah lantai kandang juga sudah bertambah, berawal hanya kandang 1 lantai, menjadi 2 lantai, dan sebagian sudah berani membangun kandang dengan 3 lantai.

Salah satu pertimbangan perkembangan ini adalah untuk mencapai hasil produksi yang maksimal dengan efisiensi biaya produksi, sehingga bisa dihasilkan keuntungan yang lebih maksimal. Dengan closed house flooring system, jumlah operator kandang sangat berkurang, karena untuk populasi 40.000 ekor, hanya memerlukan 2 orang operator kandang. Jika menggunakan peralatan manual, 1 orang operator kandang hanya untuk 5.000 ekor.

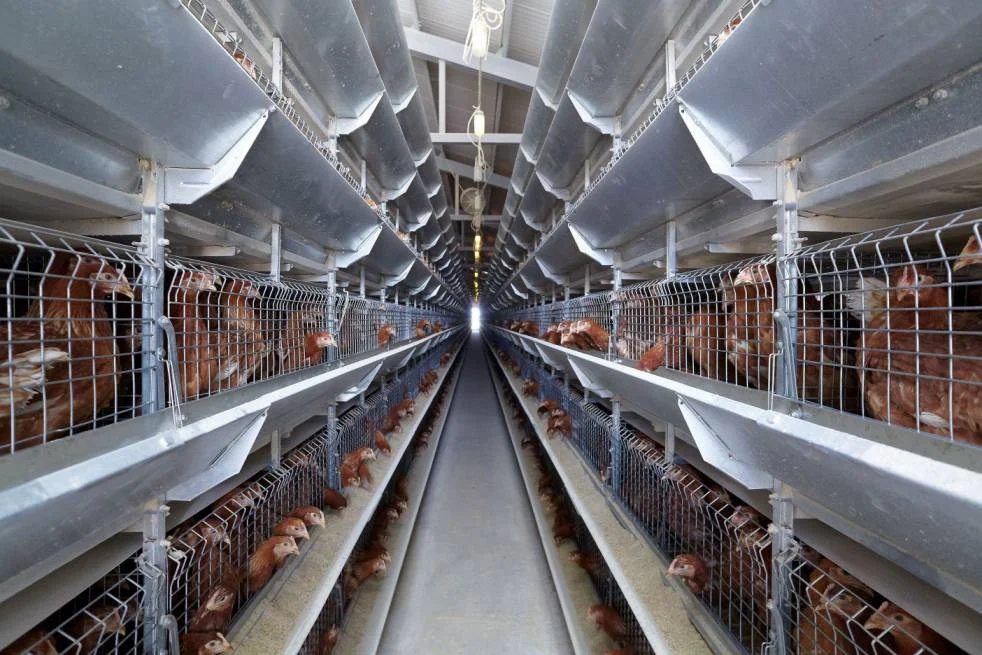

Dalam perkembangannya, saat ini sudah ada sistem pemeliharaan broiler yang lebih efisien, yaitu “Broiler Cages System”. Dengan sistem pemeliharaan ini, jumlah lahan yang diperlukan lebih kecil, operator kandang lebih sedikit, dan hasil produksi lebih maksimal. Sistem pemeliharaan ini membawa peternakan ayam broiler menjadi industri peternakan ayam broiler.

PT Ansell Jaya Indonesia, sebagai dealer TEXHA di Indonesia, memperkenalkan produk Broiler Cages Robotic. Texha, dengan teknologi inovatifnya telah menciptakan kondisi ideal untuk pertumbuhan ayam broiler. Bahan menggunakan baja berkualitas tinggi dengan lapisan zinc kelas satu, dengan meminimalkan komponen plastik, sertamenerapkan teknologi hemat energi untuk mengurangi biaya. Tecnologiuntuk proses panen yang menggunakan “ROBOT” memungkinkan kinerja produksi yang tinggi dengan biaya minimum. Teknologi robotic ini telah dipatenkan.

Watering System

Setiap tier dilengkapi dengan dua jalur drinking system, yang memberikan kemudahan ayam untuk minum. Setiap cage dilengkapi dengan 6 pcs nipple360° untuk aktivasi vertikal dan horisontal,sehingga memudahkkan ayam untuk minum dari berbagai posisi. Sambungan berkualitas tinggi dari semua bagian watering system mencegah terjadinya kebocoran air pada sistem ini.

Feeding system

Sistem ini menggunakan teknologi yang dibuat khusus untuk cage system, pan feeder “KoChiBo” dengan bagian nampannya bisa diatur sehingga kedalaman dan jumlah pakan di dalamnya sesuai dengan pertumbuhan ayam. Jadi, volume pakan yang lebih besar pada pan feeder akan diberikan saat ayam sudah besar. Kondisi ini akan menambah pertumbuhannya yang cepat.

Poultry Unloading System

Ada 3 jenis broiler unloading systemyang ditawarkan:

- Unloading secara manual

- Unloading otomatis

- Unloading sistem “ROBOT” (sepenuhnya robotized).

Teknologi inovatif “ROBOT” dipatenkan dan telah dioperasionalkan di peternakan ayam broiler terbesar, dan hasilnya memuaskan. Keuntungan dari teknologi“ROBOT” dibandingkan dengan unloading manual:

- Jumlah operator kandang lebih sedikit

- Populasi ayam yang dipelihara lebih besar sekitar 15%

- Ayam cedera saat panen berkurang sekitar 1,5 – 2 kali

- Tingkat stres ayam berkurang

Pilihan broiler unloading system tergantung tujuan produksi dan teknologi yang digunakan pada peternakan anda, tim PT Ansell Jaya Indonesia akan membantu dalam memilih metode yang lebih tepat sesuai dengan kebutuhan peternakan anda.

Lighting System

Broiler cages Texha sudah termasuk sistem pencahayaan LED didalam kandang. Menerapkan teknologi hemat energi yang dapat mengurangi konsumsi daya sebanyak 4 – 5 kali. Sistem ini menyediakan “sunrise-sun-set” yang halus, yang menghilangkan stres ayam dalam kandang dan memungkinkan penyesuaian intensitas cahaya. Pencahayaan yang seragam pada setiap cage, akan memberikan kondisi keseragaman pertumbuhan ayam. Daya tahan lampu LED adalah 50.000 jam operasional terus menerus.

Poultry Manure Disposal System

Manure belt terbuat dari polypropylene government stainless dengan ketebalan 1mm, berjalan secara otomatis dari semua tingkat dan melewati dua sisi pembersihan dengan mekanisme khusus “Scrapers-wave” yang terbuat dari baja yang dikeraskan dan digunakan untuk penggeraknya. Hal itu memungkinkan untuk menghilangkan kotoran dengan kelembaban sekitar 65%, sehingga tidak mengakumulasi kandungan berbahaya.

Untuk informasi lebih lanjut mengenai produk Broiler Cages Texha, bisa langsung menghubungi PT Ansell Jaya Indonesia di nomor +62 22 87803890 atau email [email protected]

GD0619